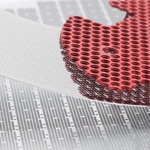

VACCO etches fine screens and meshes with through features as small as 100 microns. This screens are etched from solid sheets of material offering superior mechanical strength, excellent electrical conductivity, and reliable integrity of pore size regardless of flow characteristics. VACCO’s fine screens can be made of titanium, nitinol, stainless steel, nickel, copper, or any other material etched at VACCO, see Design Guide.

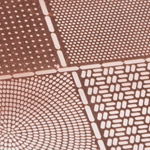

Patterns are wide ranging, from: round, elongated, hexagonal, square, octagonal, rectangular, and so on. All inside corner radii will be equal to material thickness, and the hole must be equal to or larger then the material thickness. With VACCO you have the flexibility to achieve some transmission and open area issues you cannot achieve through other methods of manufacturing.

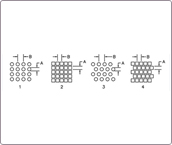

Through hole features are normally etched equally (50/50) from both sides of the process sheet. VACCO can etch at different proportions (i.e. 80/20 or 60/40) which can produce conical-shaped through hole features, helping to achieve unique flow characteristics benefiting certain applications. Review the diagram below showing the difference of a 50/50 etch profile compared to a 80/20 etch profile.

APPLICATION EXAMPLES OF SCREENS & MESHES:

- Medical reconstructive surgery mesh

- Filtration (minimum 75 microns)

- Extrusion screen for fiber and plastic

- Protective barrier filter for contamination

- Faraday shielding for medical sensors

- Air flow control for paper transport

- Sorting & Sieving

- EMI/RFI Shielding

- Carrier and Supports

- Many others