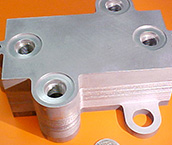

Our team fabricated PCHE by photo etching the (40) .020” thick corrosion-resistant AISI 316 stainless steel layers with flow paths and microfluidic channels. CNC machining and polishing were used to generate top and bottom plates. Through our diffusion bonding process, the multiple layers were joined creating a monolithic hermitically sealed device. The wire EDM process was used to machine the access ports and allow the part to take its final shape. The finished unit was then bubble leak tested and pressure certified. This was completed with a 12-week turnaround time.

VACCO photo etches printed circuit heat exchangers that undergo quality control procedures and rigorous testing to meet fuel cell industry part standards. For additional product details, refer to the table below and contact us.

Photo Etching of PCHE Project Highlights

- Product Name

- Printed Circuit Heat Exchanger (PCHE)

- Product Description

- These printed circuit heat exchangers are used within a Cooling System or Recuperator.

- Capabilities Applied/Processes

- Primary:

Photo Etching

CNC MachiningSecondary:

Polishing

Diffusion Bonding

Wire EDM

- Overall Part Dimensions

- Layer Thickness: 0.020”

Etching Width: 0.020”

Etching Depth: 0.010”

~Bonded height: 2”, Length: 5”, Width: 4”

- Tightest Tolerances

- ± 0.002”

- Material Used

- 316 Stainless Steel

- Material Finish

- Polished

2B Rolled

- In-process testing/inspection performed

- In-process Data Collection per our SPC Quality Procedures for IQS (part of our Six Sigma culture)

MicroVue Inspection

CMM

Comparator

Pressure Leak Tested to 900 psi for Hermetic Seal

- Industry for Use

- Fuel Cell

- Delivery/Turnaround Time

- 12 weeks

- Delivery Location

- Northeastern United States

- Standards Met

- Customer Specifications, 2D CAD Drawing